In gardening projects, corten steel has become the new favourite of modern landscape architects and developers due to its unique corrosion resistance, non-maintenance requirements, and artfully rusted appearance, while common steel (mild steel) falls due to its susceptibility to corrosion. This blog will help you make a better choice by comparing the key differences between corten steel and common steel for garden applications.

Comparison of Material Properties: weather resistance and strength

The essential difference between Corten steel vs ordinary steel is the alloy composition; Corten steel,also known as weathering steel, is a high-strength, low-alloyed steel (ASTM A588 standard) with additions of copper (0.2-0.5%), chromium and nickel, which form a dense rust layer (50-100 μm thick) that dramatically improves corrosion resistance. This “living rust” system allows it to “ fix itself ” outdoors, without additional protection. In contrast, ordinary steel lacks these alloys and is highly susceptible to rust, leading to structural failure.

It has been noted that the weathering resistance of weathering steel is 4-8 times higher than that of ordinary carbon steel. Measurements in urban environments show that weathering steel loses only about 0.8mm in 40 years (only 2.0mm in 120 years), while ordinary mild steel will continue to rust and gradually perforate without protection. This means: in the same time, weathering steel material loss rate can be about 25 times slower than ordinary steel, equivalent to 200 times slower than cheap steel, longevity is much longer than ordinary steel.

Weatherability/Corrosion Resistance:

Corten steel naturally forms a dense protective layer of rust upon exposure, significantly delaying further corrosion. In contrast, without spray, ordinary steel accumulates corrosion, which accelerates when exposed to moisture.

Mechanical Properties:

Weathering steels retain high strength and toughness; the tensile strength is superior to ordinary mild steel. Therefore, corten steel can withstand higher loads and have a longer service life for the same thickness, while ordinary steel requires a thicker plate to achieve the same life.

Application Scenario Differences

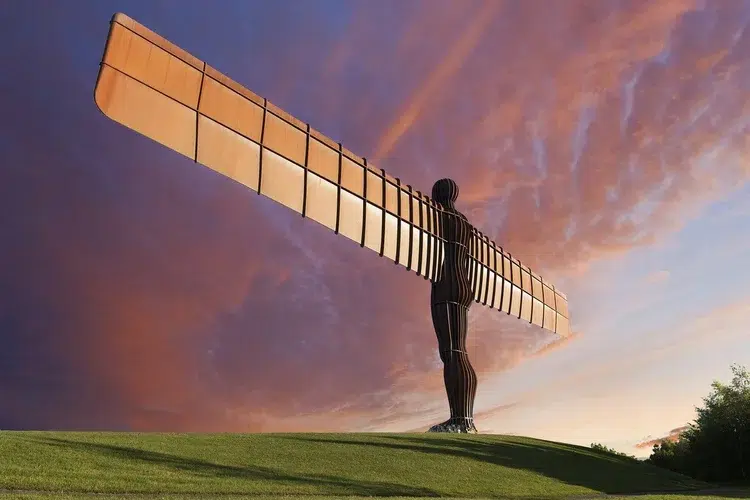

Weather-resistant steel has been used in a wide range of horticultural and landscaping projects for park sculptures and building facades, and is also commonly used in a variety of products such as planters, flower beds, landscape railings, customized trellises, and water features. Its weather resistance makes it suitable for a variety of environments including coastal, industrial and urban.

Corten steel is widely used in garden applications:

Landscape Edging & Fencing: 2-4mm thick, linear design, suitable for separating lawns and paths.

Planters and planting boxes: rectangular or round series, diameters/sizes 0.5-3m, with integrated drainage system.

Decorative: fountains or artistic sculptures, pre-rusted options to accelerate the aesthetic formation.

Ordinary steels are mostly limited to simple applications indoors or protected by paint, such as temporary fences, but are prone to deformation outdoors. The 2025 trends show that Corten steel rising to 28% in gardening, due to the combination of industrial aesthetics and natural textures.

Corten Steel vs. Common Steel: in garden applications

1. Residential gardens: Corten steel is used as flower plant boxes, where the rust color complements the greenery and creates a sense of “rust”; regular steel requires regular painting and is prone to soil contamination.

2.Commercial landscapes: in hotels or parks, Corten steel is used as a green screen, reducing annual maintenance costs by 45%; ordinary steel deteriorates quickly in high-traffic areas.

3.Public spaces: in urban greenways, Corten steel has a weather-resistant life of more than 35 years; ordinary steel is prone to vandalism.

4.Special environments: in coastal areas, Corten steel’s corrosion resistance to salt spray is as low as 1/6 that of ordinary steel.

The recyclability and environmentally friendly properties of corten steel are also in line with sustainability. Weathering steels do not require painting, thus avoiding the environmental impact of volatile organic compounds (VOCs) in paint. At the same time, discarded weathering steel can still be returned to the furnace for reuse. The natural oxidation process of corten steel also reduces waste and pollution from maintenance and achieves a lower environmental footprint.

Aesthetic and design influences: the artistry of the rust-colored exterior

In gardens and landscapes, the unique ochre-colored patina appearance of corten steel solidifies on the surface over time, taking on a variety of shades of copper-red, brownish-brown and more. This natural rust color creates a strong contrast with natural elements such as greenery and stone, and also provides a layering effect that cannot be easily replicated by ordinary steel, as the ambient light changes. In contrast, common steel, when exposed outdoors, suffers from uneven patina and progressive corrosion, and must be painted or coated regularly to maintain its aesthetic appeal.

The warm patina that corten steel develops over time blends seamlessly into the surrounding grass and skyline. This patina is not only aesthetically pleasing, it is also self-healing: if the surface is scratched or exposed, a new layer of patina gradually builds up in the area, restoring a continuous protective film. Thus, weathering steel can be used as decorative elements in the landscape while maintaining their structural safety over the long term. This “aged patina” is a design tension that cannot be achieved with ordinary steel in a durable condition.

Maintenance Requirements and Service Life

Once the protective rust layer is formed, corten steel rarely requires additional painting or anticorrosion treatment. Studies have shown that weathering steel offers the most cost-effective performance over a life cycle of more than 10 years because it does not need to be repainted for maintenance. In contrast, ordinary steel must rely on painting and spraying to protect against corrosion and requires re-maintenance every 10-12 years. This constant maintenance not only increases long-term costs, but also brings construction annoyance and environmental pollution.

| Feature | Corten Steel | Common/Ordinary Steel |

| Weathering Resistance | Extremely high. Stable corrosion resistance after the formation of a surface rust layer, and weathering resistance of about 4-8 times that of common steel. | Easily rusts, corrodes rapidly especially in humid or salty environments. |

| Maintenance Requirements | Almost no required maintenance. Self-protection by natural oxidizing layer, coating or repainting is not required. | Requires regular painting or anti-rust treatment and requires overhauling and refurbishment every 10 years; otherwise, it will continue to corrode. |

| Lifespan | Over 25 years. With proper thickness, can use decades or even 100+ years. | If unprotected, susceptible to severe corrosion within 5-10 years; even if galvanized or coated for protection, service life is limited by the aging cycle of the coating. |

| Appearance Effect | Produces a uniform brownish-red/patina color over time, with a natural texture that harmonizes with vegetation and the environment | Appearance is dependent on the color of the coating; natural rusting is irregular and unprotected, resulting in mottled patina that impacts aesthetics. |

| Initial Costs | Higher. Plate prices are approximately 15-20% higher than regular steel | Lower. Ordinary steel is cheap |

| Life Cycle Costs | Lower. No need for repainting, lowest total cost of maintenance, highest long-term return on investment. | Higher. Requires regular maintenance and replacement of parts, the total cost of ownership rises as maintenance costs accumulate. |

Economic Benefits: Long-Term Investment Costs

While cost control is important to landscape designers and developers, even more critical are the full life cycle economic benefits. While the initial unit cost of corten steel is slightly higher than that of common steel, data shows that weathering steel offers a far greater return on value than other metals on projects with an expected life cycle of more than 10 years. The explanation is that weathering steel is only about 15-20% more expensive than galvanized or painted common steel, which requires repeated maintenance; over time, the initial price advantage of common steel is quickly offset by the cost of repeated painting.

In addition, corten steel reduces the risk of accidents and maintenance uncertainty. For example, in public gardens and urban green spaces, steel flower planters, landscaping, etc., are often exposed to sun and rain for years. If you choose ordinary steel, you will need to allow for multiple maintenance periods and budget.

Summary

Corten steel shows significant advantages in landscaping applications, from weather resistance and appearance to maintenance requirements and cost of ownership.Corten steel is virtually irreplaceable, especially for garden landscape projects that seek long-term quality, low maintenance and high return on investment.Please contact us for more case studies and technical support on corten steel applications.